We understand the industry and can talk your language.

Supply stainless steel and specialist metal parts to the Lift industry. We work with stainless steel, aluminium, brass, copper and specialist patterned stainless steel materials. Along side the metal products we work with glass, plastics, timber, leather and other materials.

We provide high end solutions to hotels and residential applications in specialist finishes with intricate details.

We both work with our client on larger projects, but also have the capacity to be reactive to the needs of the on site installation and service engineers. In many cases same or next day service from an engineers sketch.

Complete lift cars

Lift doors

Re-skins

Architraves

Ceilings

Flooring

Complete Lift Interiors

Bump rails

Skirtings

Hand rails

Car Fronts

Safety glass Mirrors

Specialist metal mirrors for harsher environments

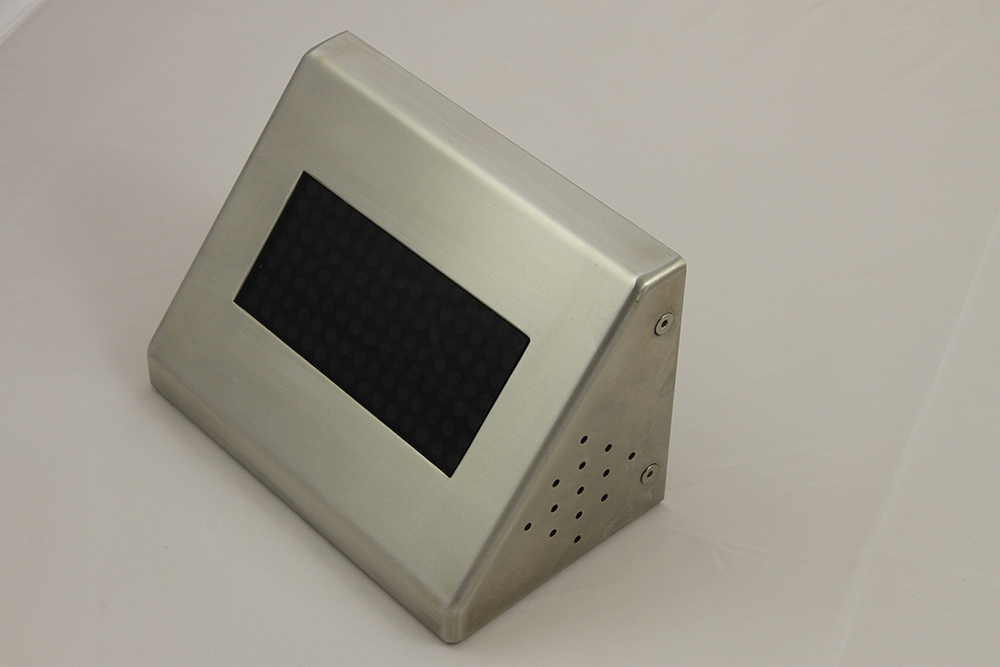

Landing indicators

Call panels

Car Operating panels

Counterweight screens

Guarding

Our workshop incorporates full in house manufacture of stainless steel and timber parts. Our CNC processes ensure quality and consistency.

Lift Interiors

AVS create lift interiors in both traditional and modern materials with attention to detail in design, customer friendliness and ease of cleaning.

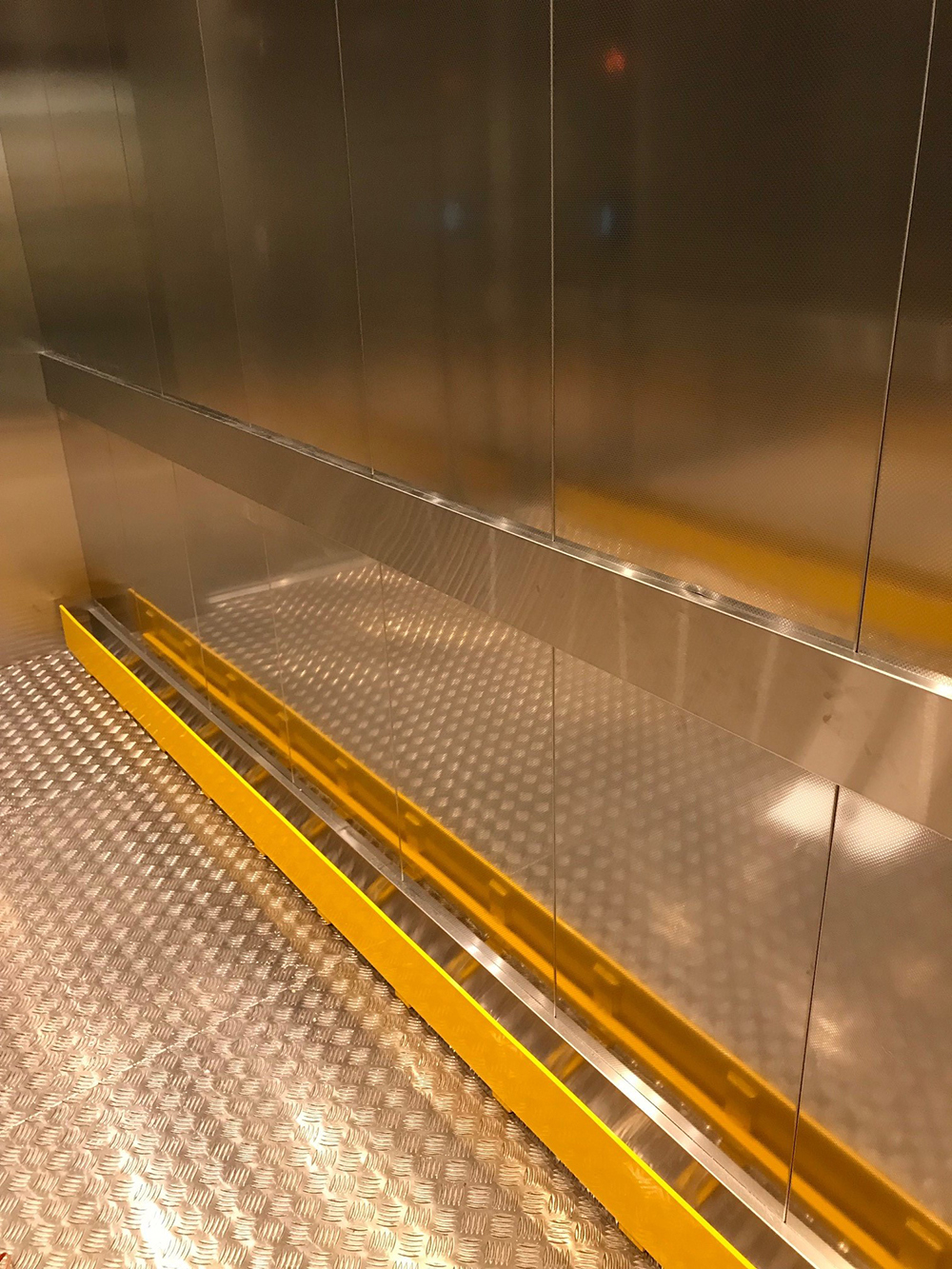

For goods lifts we work with the customer in considering the finishes and tailoring the protection to suit the usage, keeping the interior looking at its best.

We work in high end hotel and residential lifts where specialist finishes of glass, wood and patinated metals are required. Attention to detail and interfaces between finishes is paramount.

AVS offer a full survey, measuring and design service. We can provide visualisations and full CAD drawings for interiors to help the customer foresee their final product.

OUR EXPERIENCE IN BOTH DESIGN AND MANUFACTURING ALLOWS US PUSH THE INNOVATIVE BOUNDARIES AND BRING YOUR CONCEPTS TO LIFE.

Based in Maidstone, AVS have an excellent team of experienced engineers, automated factory facilities, process control and a carefully selected supply chain to ensure we deliver our ethos of first class service and quality.

Please call us for advice on design materials and finishes. We also offer design and education sessions.

Case study

The challenge

AVS and our lift partner worked with a client with a large estate of lifts to reduce their maintenance and running costs, improving their green footprint through a program of modernisation of interiors, ceilings and lighting . In some cars we have redesigned the interiors but principally the aim was to redesign the ceilings in stainless steel to allow the same solution to be fitted to a range of different size lifts, with new LED lighting to create an even coverage, lower running costs and easy maintenance.

Old Estate

Damaged interiors

High energy usage fluorescent lighting

lamp life 7000-15000 hours

Take lift out of service to change the lamps

Lamp change time minimum 1 man hour (with 2-3 men)

New Estate

Re-designed interiors with better protection and materials that will look fresher for significantly longer

Low energy LED down lighter used (60% saving on energy)

Triggered lighting to save energy when lift not in use

Lamp life improved 30,000 - 50,000 hours

Lamp changing by single person while lift in service

Lamp change time <10mins

Smarter more modern look

PROVING THAT AVS ARE MORE THAN JUST A METALWORKER